DARA Pharma develops turn-key solutions to process cartridges in nest

Press note published in EnFarma (Manufacturing Special Issue) and Pharmatech (May-June) in which Dara Pharma presents turn-key solutions to process cartridges in nest.

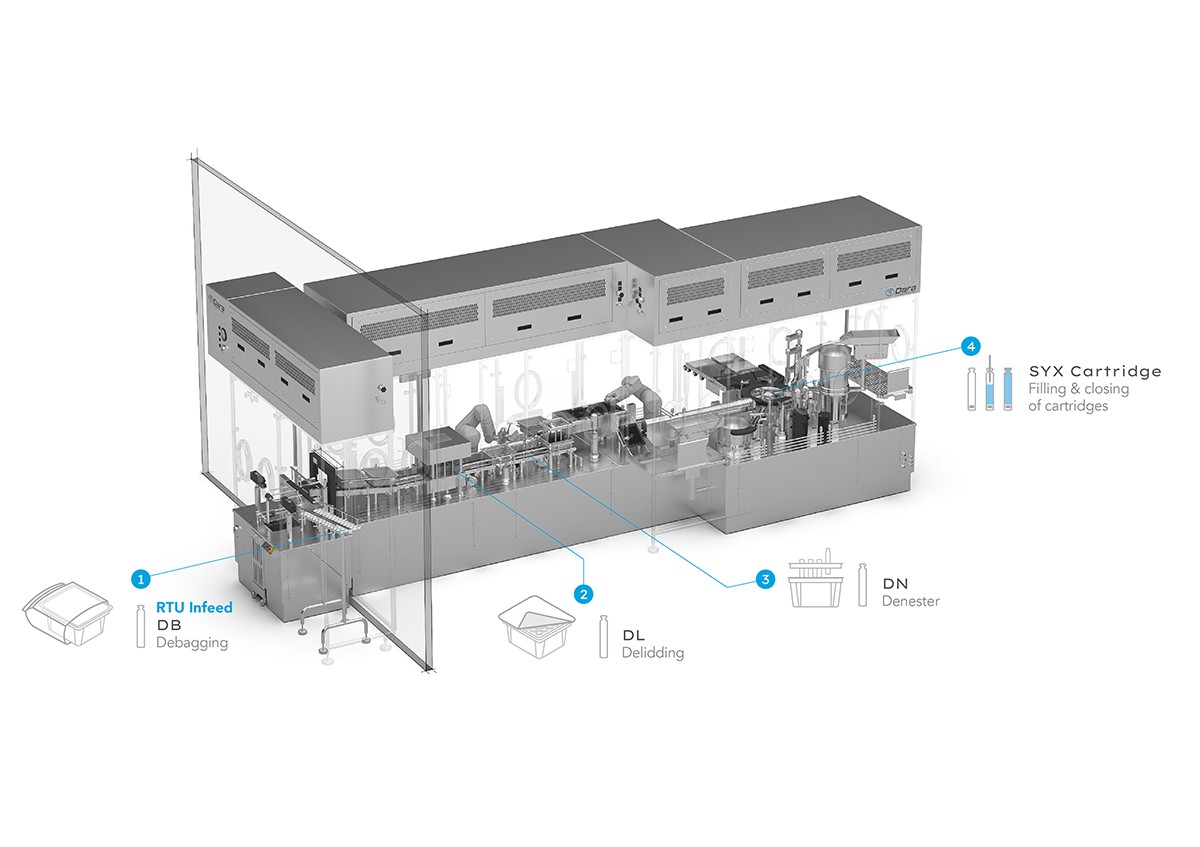

As a leading manufacturer of aseptic packaging equipment for the pharmaceutical and biotech industry, DARA Pharma keeps expanding its range of turn-key solutions by introducing a complete line for the processing of cartridges in nest.

This line integrates debagging, delidding and denester modules together with the SYX-E Cartridge filling and closing machine to process glass cartridges with an output of up to 8,500 uph.

One of the advantages of the Ready To Use format is that the cartridges arrive sterile and ready for processing. Using this working concept neither washing nor sterilization is necessary, with the saving that this means in terms of equipment and consumption.

The filling process in this line is made in two stages. In the first stage, 80% of the cartridge body is filled by means of 3 possible dosing systems: peristaltic (with SpeedFill® pumps), volumetric (with rotary piston pumps without valve), or time-pressure.

In the second stage, the cartridge is flushed, filling the remaining 20% to the rim. For a maximum precision, this process can be made using 3 technologies: overfilling, filling with laser detection, or plunger displacement with laser detection.

Another remarkable point is that DARA Pharma offers this line under different containment systems, either Isolator, cRABS, oRABS or LAF, depending on each need and environment.

This line's equipment has been designed for its use in sterile areas, according to cGMP and US FDA standards, in conformity with the requirements of the pharmaceutical and biotechnological industry.