Dara Pharma’s line for GE Healthcare takes the spotlight in the Irish market

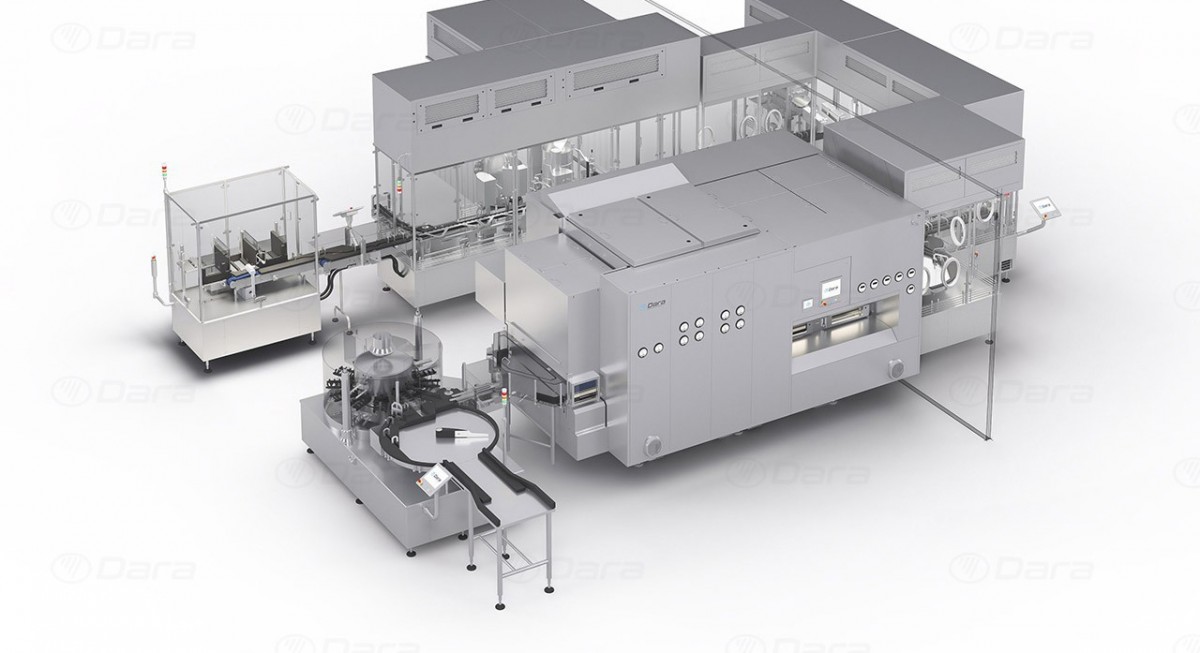

A turn-key solution for vials and bottles from 10 ml to 1 litre.

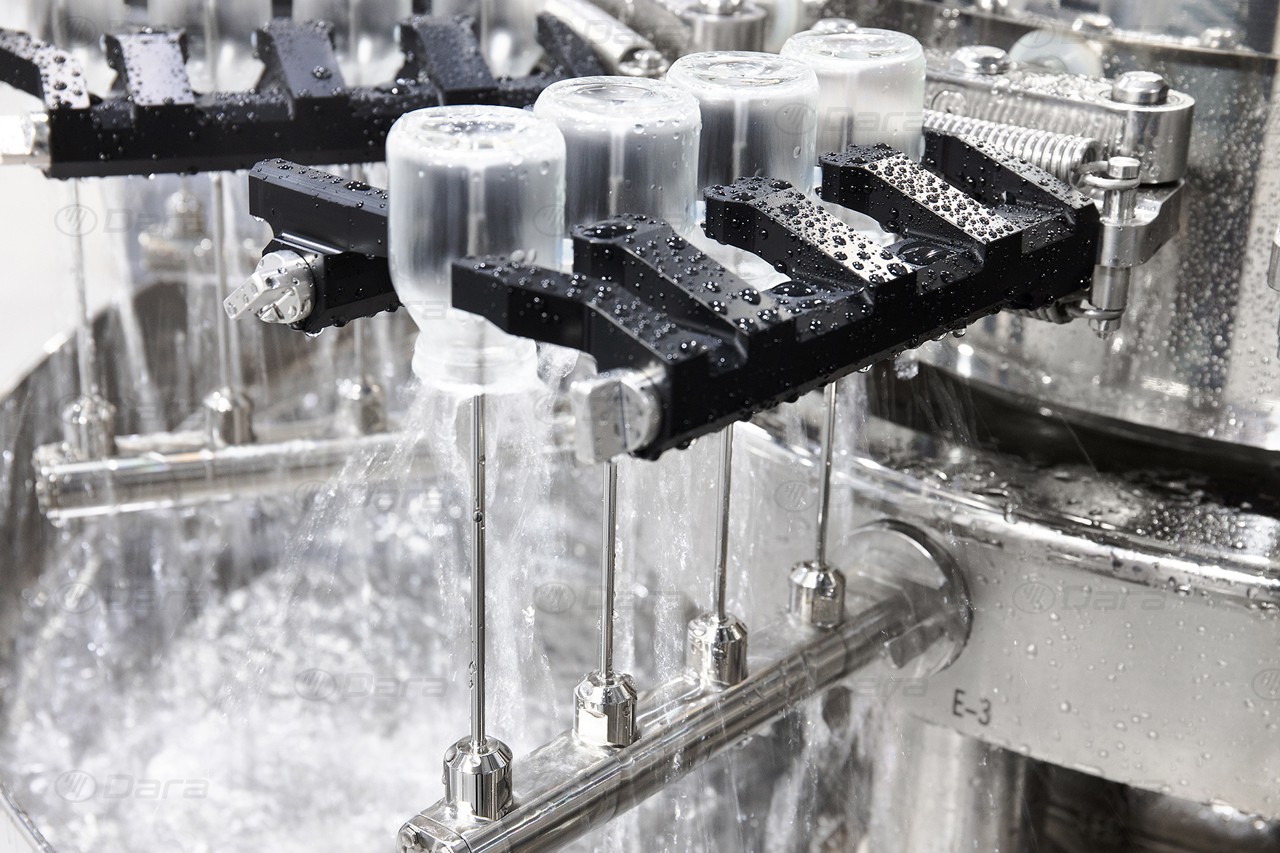

Following our well-known “Flexibility in Motion” philosophy, Dara Pharma developed for the multinational company GE Healthcare a fully integrated line to process a wide range of vials and bottles in a wide range of sizes, starting from 10 to 200 ml for the glass vials, and from 50 and up to 500, 750, and 1,050 ml for the plastic bottles.

Our equipment’s versatility and flexibility make it possible to bring these processes of filling large and small formats together into one line, named RWM + DT + HSL-PP/R + Trayloader. In fact, this unique configuration can process any size of vial or bottle size. This type of flexibility demonstrates Dara Pharma’s unique value proposal in the market, and our ability to serve the top companies of the industry, while complying with the GMP - US FDA regulations.

This solution, reaching an output of 12,000 uph, passes vials and bottles through the same rotary washing machine (RWM) and depyrogenation tunnel (DT), with the plastic bottles being treated at a lower temperature. The filling and closing machines are installed in two different rooms. While the filling unit is capable of processing formats from 50 ml to 1L, the closing machine is also characterized by versatility – capable of applying multiple closures, like alu caps, screw caps, or snap-on caps. Additionally, the double Trayloader system loads both formats at a maximum capacity of up to 6 1-litre bottles in one single tray.

In the following link, you can watch the production sequence of this filling line for both formats processed: https://www.dara-pharma.com/en/machinery-selector/1-dara-pharma-aseptic-filling-machinery/164-complete-lines-for-processing-of-vials-and-bottles.

Also notable about this project is that, due to pandemic travel restrictions, Dara Pharma and GE Healthcare carried out a virtual FAT (Factory Acceptance Test), with this being the first time that we remotely executed all acceptance tests for such a complex line. We provided GE Healthcare technicians with all the necessary resources to carry out the corresponding verifications virtually. The client was completely satisfied with this validation procedure, approving the line for its installation at their plant in Cork (Ireland). This unconventional interaction on the FAT reinforces our values of adaptability and flexibility, under any circumstances.

Learn more about this project for GE Healthcare in this piece by our partner, BioPharma Engineering. Additionally, IDA Ireland has published an article about the plant opening, and even the Radio & Television of Ireland (RTE) has reproduced the information about this new site, for the construction of which Dara is proud of having contributed with our cutting-edge aseptic packaging technology for pharmaceutical and biotech industries.